Go Back

- Your Solutions

- Products

- Services

- Industries

- Contact

Depending on the axis of motion, the installation space in robot arms becomes smaller and smaller. Nevertheless, the load carrying capacity or rigidity must not suffer as a result. Thin-walled deep groove or angular contact ball bearings are ideal for such an installation environment. For example, so-called flex bearings with rings of different widths are used in shaft gear units. In operation, an elliptical disc elastically deforms the ball bearing to produce backlash-free and precise motion.

Or do you need a versatile solution with maximum rigidity for your industrial robot? Then we recommend one of our crossed roller bearings. Available with split inner or outer ring on request. Gladly adapted to all further needs of your application.

Your requirements

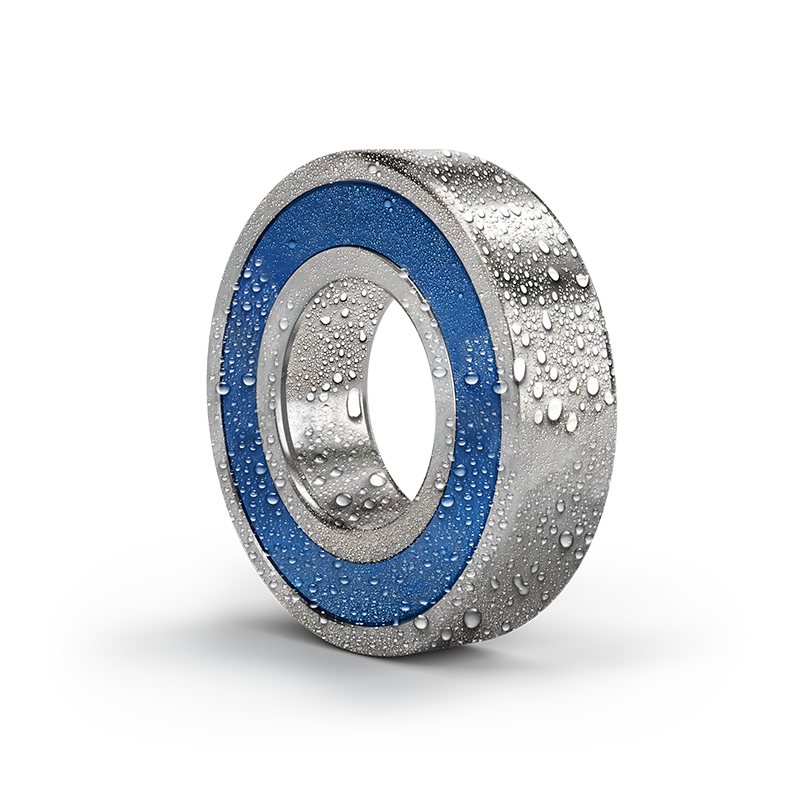

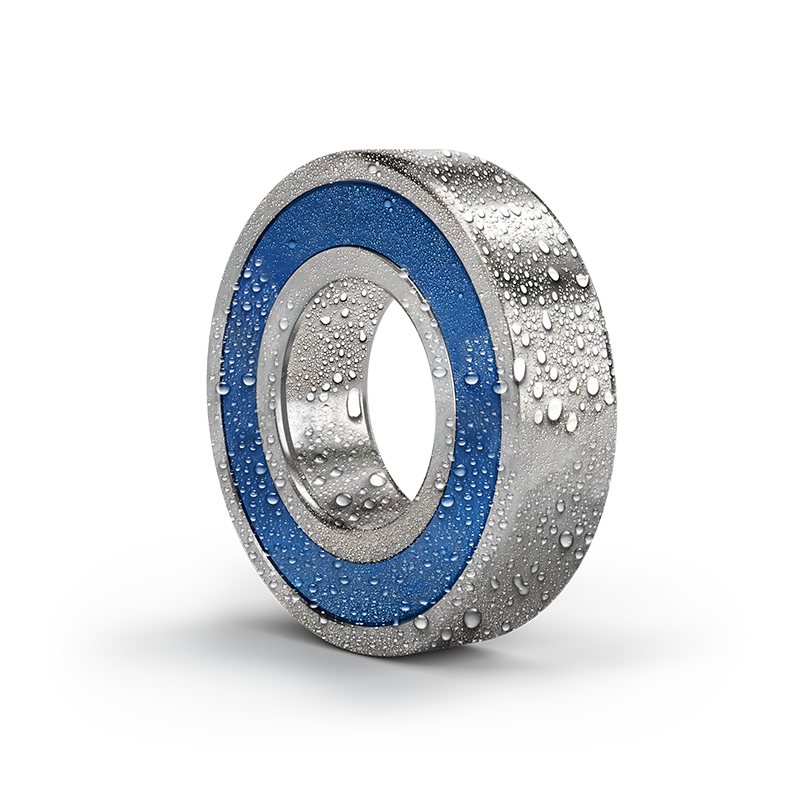

When it comes to production machines and their interlinking, the entire system is only as good as the weakest link in the process chain. Compromises in terms of service life or reliability are therefore out of the question. For your ball bearings, we recommend a high-performance seal to minimize grease leakage and dust or splash water ingress.

To prevent corrosion, stainless steel bearings are standard in the food industry. The sealing material must be DEHP free and we offer multiple food grade grease options. Our experts will be happy to advise you on the optimal materials suited for your application.

Your requirements

The healthcare and life sciences sectors are increasingly turning to automation for efficiency, accuracy, and repeatability. From robotic sample handling and medication dispensing to automated imaging systems and diagnostic platforms, motion control is at the heart of today’s most advanced medical and laboratory equipment.

CW Bearing delivers miniature, quiet, and low-torque bearing solutions designed for compact automation platforms that require long service life, cleanliness, and zero tolerance for failure. Our bearings support robotic systems used in clinical laboratories, diagnostic imaging, pharmaceutical R&D, and hospital automation; environments where uptime, safety, and hygiene are essential.

Your requirements

Low torque for precise, smooth motion

Compact, lightweight bearing assemblies

Quiet operation in clinical environments

Sterilization-resistant lubricants and materials (where applicable)

Long service life with minimal maintenance