Go Back

- Your solutions

- Products

- Services

- Industries

- Contact

Depending on the axis of motion, the installation space in robot arms becomes smaller and smaller. Nevertheless, the load carrying capacity or rigidity must not suffer as a result. Thin-walled deep groove or angular contact ball bearings are ideal for such an installation environment. For example, so-called flex bearings with rings of different widths are used in shaft gear units. In operation, an elliptical disc elastically deforms the ball bearing to produce backlash-free and precise motion.

Or do you need a versatile solution with maximum rigidity for your industrial robot? Then we recommend one of our crossed roller bearings. Available with split inner or outer ring on request. Gladly adapted to all further needs of your application.

Your requirements

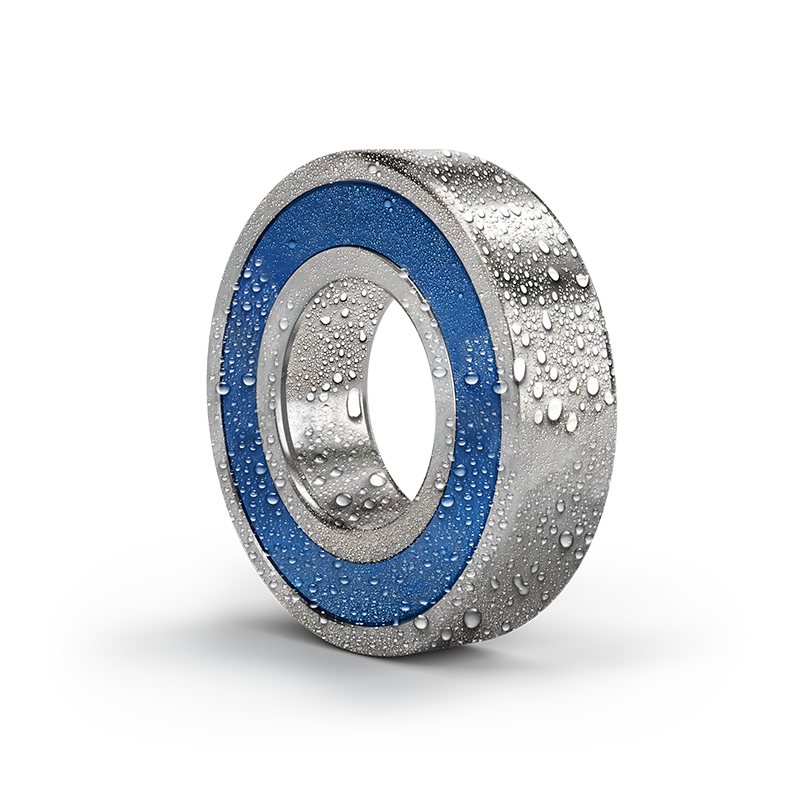

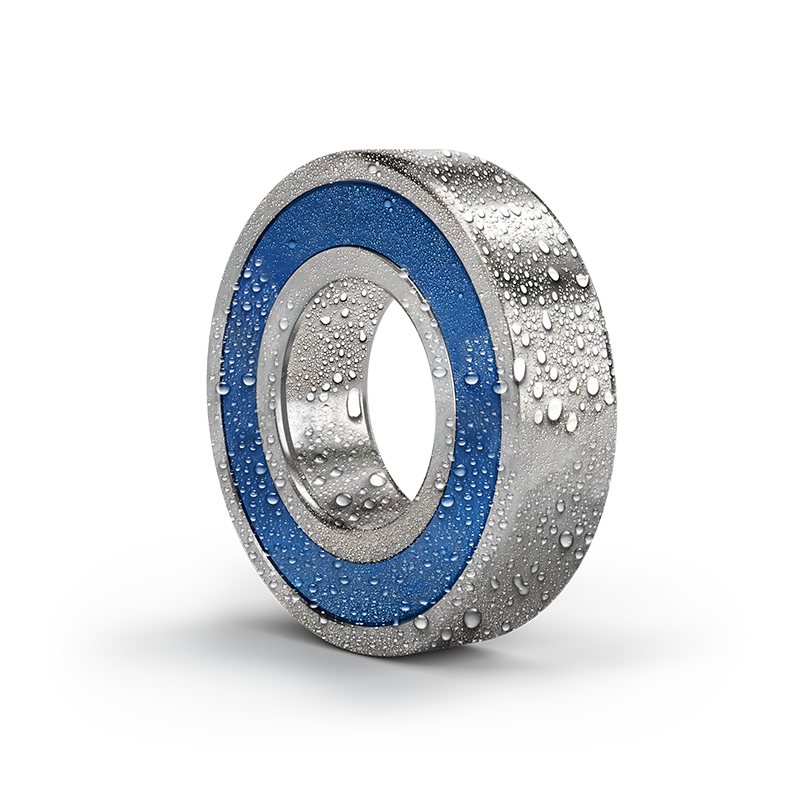

When it comes to production machines and their interlinking, the entire system is only as good as the weakest link in the process chain. Compromises in terms of service life or reliability are therefore out of the question. For your ball bearings, we recommend a high-performance seal to minimize grease leakage and dust or splash water ingress.

To prevent corrosion, stainless steel bearings are set in the food industry. The sealing material must be free of DEHP. In addition, the greases must be approved for foodstuffs. Our greases are also listeria-inhibiting. Our experts will be happy to advise you on the selection of the grease optimally suited to your application.

Your requirements

With the practical ball bearing configurator from CW Bearing, you can easily put together your individual solution and receive the corresponding quotation directly on request.

Do you have specific questions about a rolling bearing in your application? Then please feel free to contact me directly.