Go Back

- Your solutions

- Products

- Services

- Industries

- Contact

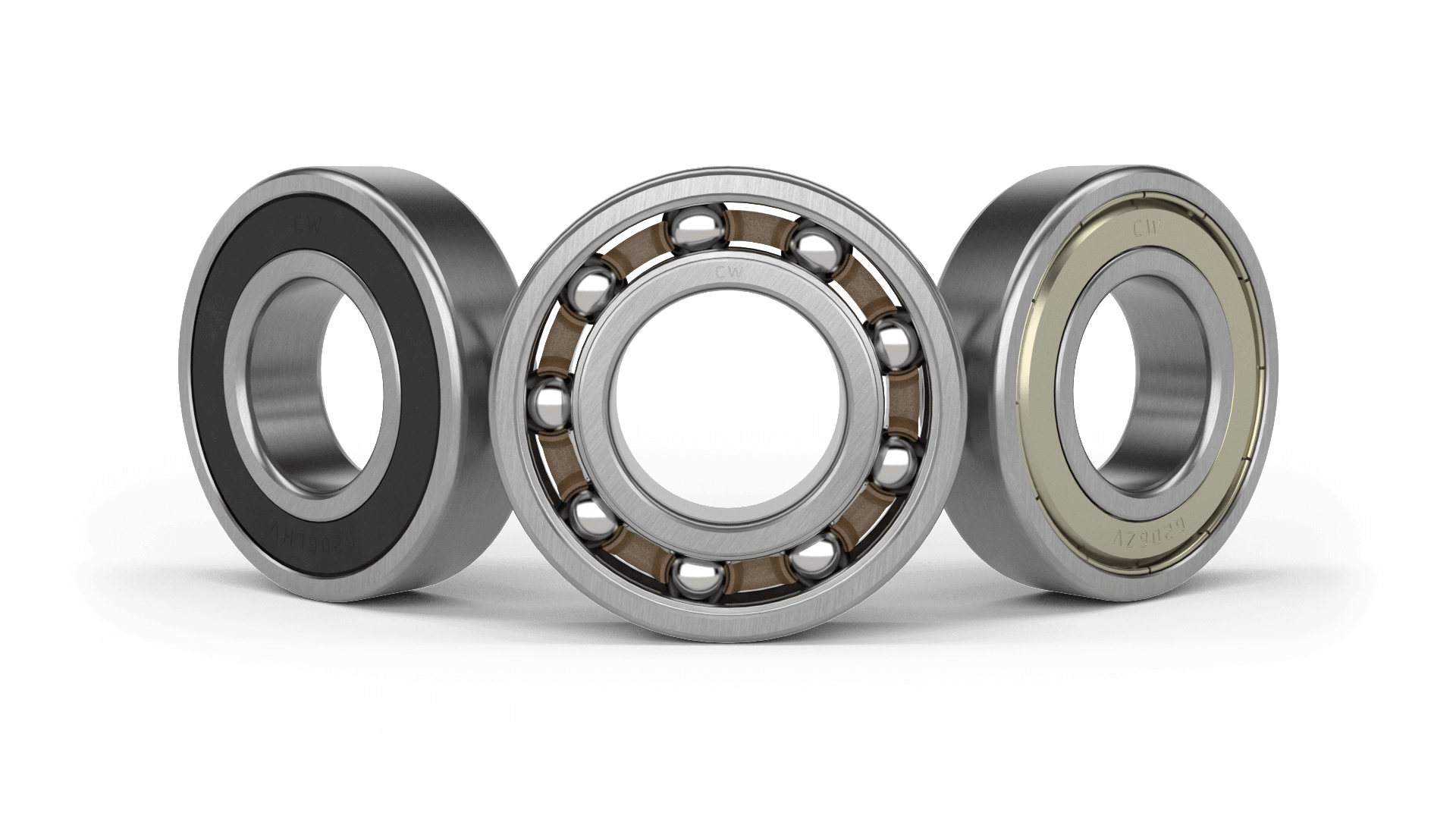

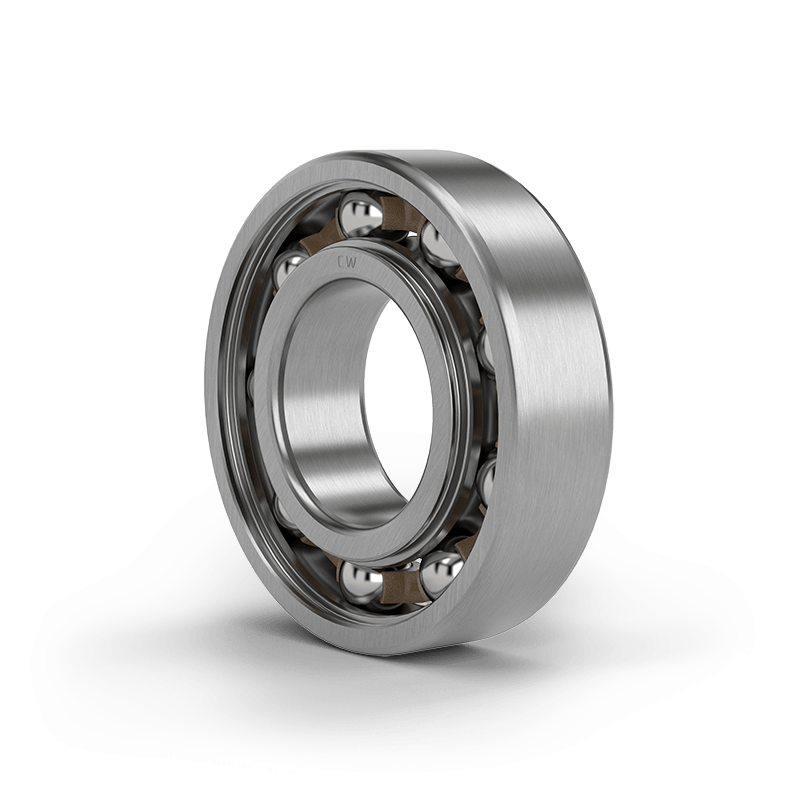

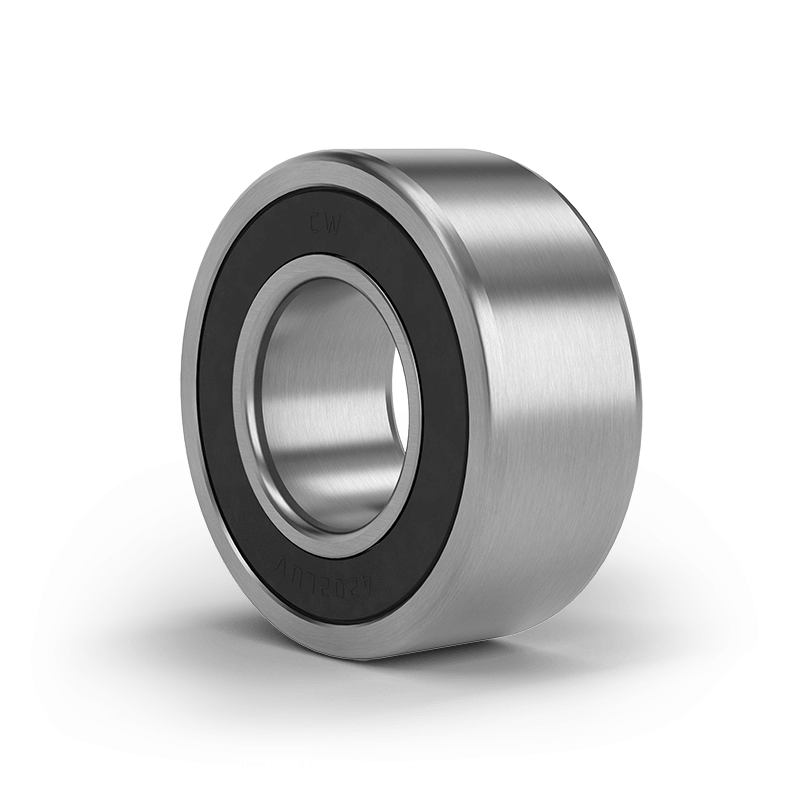

Deep groove ball bearings are self-retaining and can support axial forces on both sides in addition to radial forces. They are particularly cost-efficient, easy to maintain and versatile. If seals are required, deep groove ball bearings offer a wide range of options depending on sealing effect and friction.

Due to their point contact between raceway and ball, deep groove ball bearings are extremely low-friction. In addition, they are suitable for particularly high speeds and even then offer low-vibration and quiet running. This makes deep groove ball bearings ideal for all types of electrified applications. Deep groove ball bearings from CW Bearing trimmed for efficiency are already making an important contribution to reducing CO2 emissions.

Of course, we also manufacture special dimensions for you, supply special seals or make any kind of adjustment to the outer ring. Upload your specifications on our homepage or simply contact us. We will be very happy to advise you personally on the technical details.

From a bore diameter of less than 10 mm, these are referred to as miniature deep groove ball bearings. Their design and mode of operation correspond to the larger deep groove ball bearings. Thanks to their small dimensions, they are suitable for very compact applications with extremely high speeds.

Do you need a special radial clearance, a special grease or a flange on the outer ring? For individual adaptations of your miniature bearing, the comprehensive CW configurator is at your disposal.

Series such as 68 and 69 (or 618 and 619) are significantly smaller and narrower than series such as 60, 62 and 63 with the same bore diameter. Thin-walled bearings are therefore ideally suited to shafts with a relatively large diameter and little free installation space.

With the design-related small and light balls, very high speeds can be achieved in vehicle transmissions, for example. For shaft drives in robotics, our application experts have designed a large number of special bearings, each with inner and outer rings of different widths.

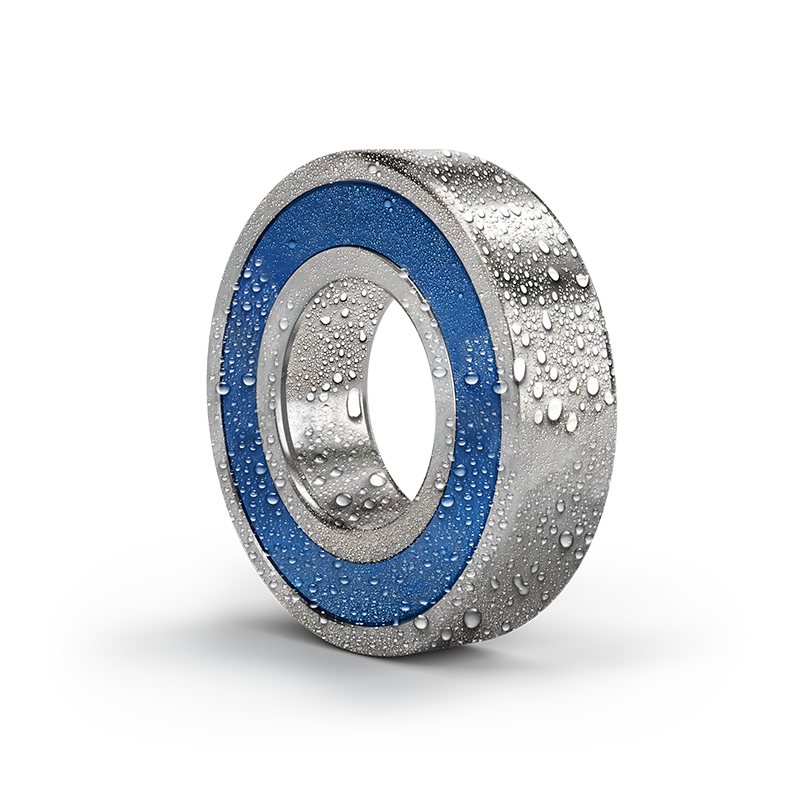

When it gets wet in forestry tools or food applications, stainless steel bearings are indispensable. In the case of aggressive media, we recommend our high-performance steels. We will be happy to advise you on the choice of the right grease. For food applications greases with H1 certificate are set. Our greases are also listeria inhibiting. For outdoor applications, use special greases with good emergency running properties.

Do you want to play it safe? Then go for solid lubricant. Friction causes the polymer matrix to release the lubricant. At the same time, it provides 100% protection against dust or splash water ingress. If desired, it can also be listeria-inhibiting. No matter what you decide. We supply you with the perfect solution.

With CW Bearing's practical ball bearing configurator, you can easily put together your individual solution and receive the corresponding quotation directly on request.

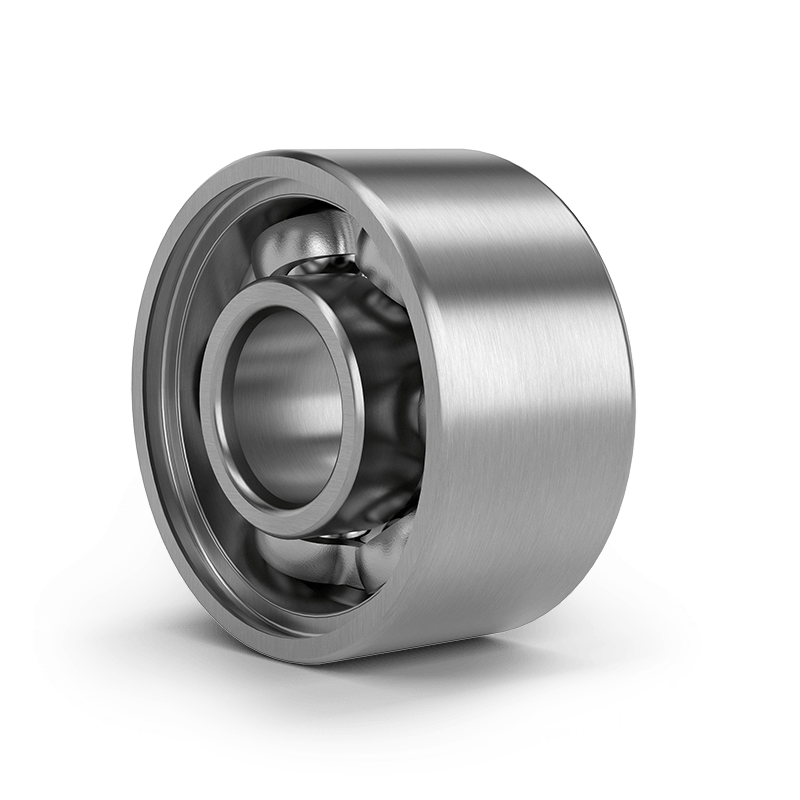

In principle, the operating principle of double row deep groove ball bearings corresponds to that of single row. Double row deep groove ball bearings are also suitable for radial and axial loads in both directions.

With more balls, they offer higher load carrying capacity than a comparable single row deep groove ball bearing. They can also accommodate tilting moments very well. Therefore, double row deep groove ball bearings are ideal for particularly short shafts with limited installation space.

On request, double row deep groove ball bearings are also available from CW Bearing with shields and lip seals.

Do you have specific questions about a rolling bearing in your application? Then please feel free to contact me directly.