Go Back

- Your solutions

- Products

- Services

- Industries

- Contact

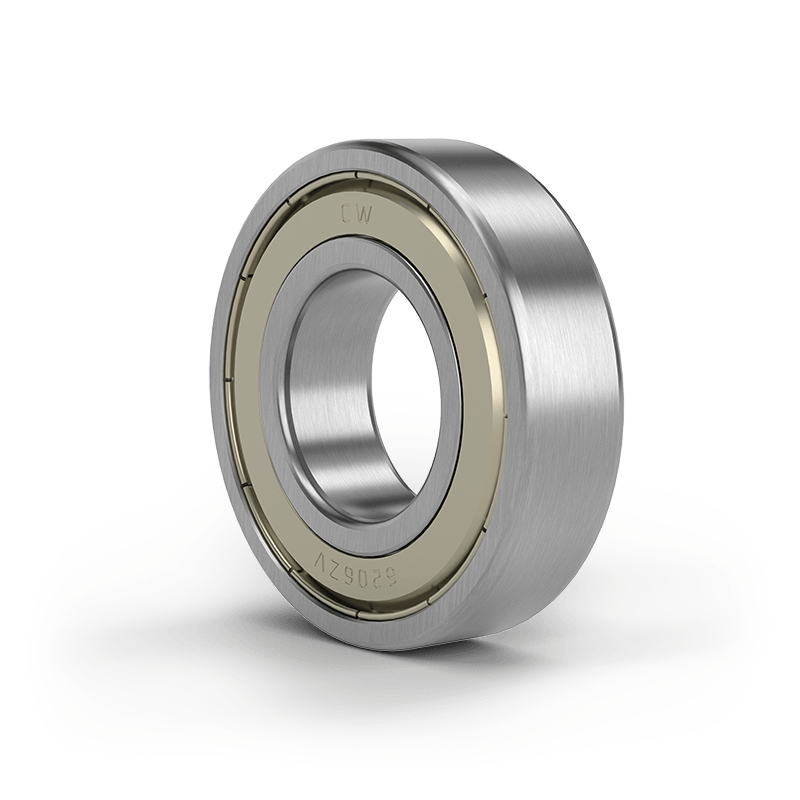

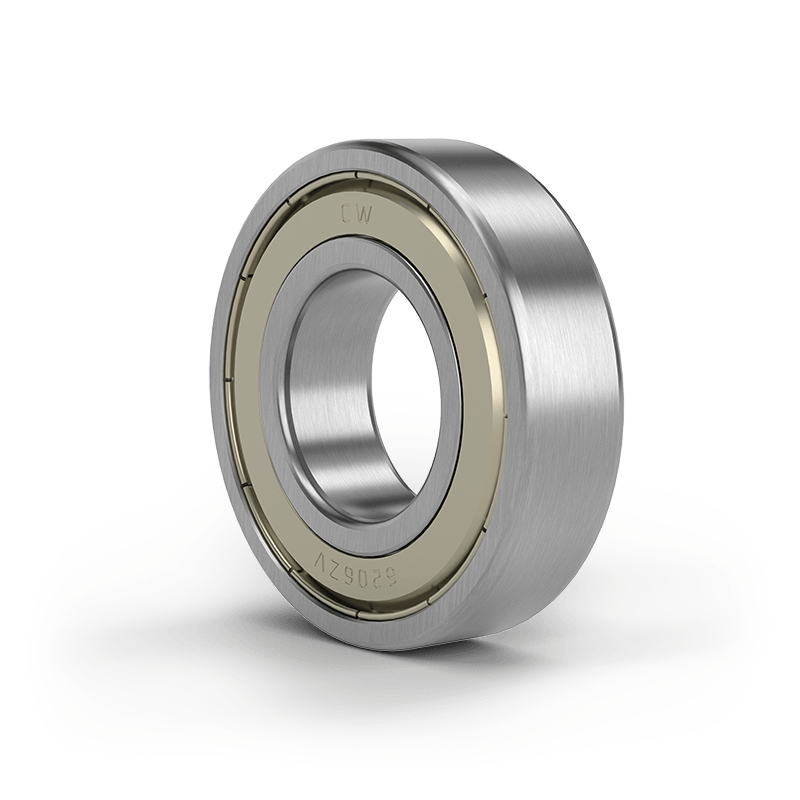

Significant energy can be saved at this bearing point on your bikes! On the one hand, the sealing friction should be kept as small as possible. On the other hand, the ball bearing must have a seal that reliably protects against splash water and dust.

Our bearings with solid lubricant offer you even more protection. The goal is the longest possible service life and low maintenance requirements with maximum energy efficiency. We will find your optimum solution for you!

Your requirements

Noise is absolutely taboo here. Maximum energy efficiency is also a prerequisite. In addition, high loads and torques must be absorbed. Once again, maximum service life and long maintenance intervals are crucial.

In the development of bottom brackets, we have been the partner of various well-known manufacturers of electric bicycles for many years. Take advantage of our first-class expertise. So you can fully concentrate on your future topics such as sensor technology or software.

Your requirements

In the electric motor, power density matters. Less installation space and weight means less energy demand and lower overall costs for your bike. With the particularly low-friction and quiet bearings from CW Bearing, you reduce energy requirements and noise development.

Your requirements

Another particularly critical bearing point of the bicycle is the steering. Here, the bearings must be free of play, robust and safe. Noise is not tolerated in either the steering or the chassis. A frequent cause is small particles that penetrate the bearing.

Which seal best protects against this? Just ask the experts at CW Bearing. Our seal kit can be combined with really all ball bearing designs. And if that is not enough, we will develop a solution for you with a special seal. In this way, you extend service life and maintenance intervals to the absolute maximum.

Your requirements

With CW Bearing's practical ball bearing configurator, you can easily put together your individual solution and receive the corresponding quotation directly on request.

Do you have specific questions about a rolling bearing in your application? Then please feel free to contact me directly.