Go Back

- Your solutions

- Products

- Services

- Industries

- Contact

Your customer-specific requirements and expectations of the quality of our products are at the center of everything we do. For each and every one of the 600 million rolling bearings we produce each year, we have set ourselves the "0-defect policy" as our goal.

Our processes, which have been audited many times by demanding automotive customers, vouch for our quality and brand promise.

Of course, we only produce for you in our own plants, which are all certified according to DIN EN ISO 9001 and IATF 16949. As a matter of principle, we have the claim to permanently improve ourselves and to sustainably invest in new production capacities.

To get your product ready for series production, we have set ourselves the highest standards. The basis is the APQP process - starting from the product idea to series production readiness. For your sampling, we fulfill the common standards according to VDA Volume 2 or according to AIAG (PPAP). Your customer-specific requirements complement our process.

On schedule, we provide you with the required product samples as prototypes or from series production. Our flexible project managers in Germany take care of delivery, the associated documentation and coordination with our plants.

Do you have specific questions about a project or a sampling? Then please feel free to contact me directly.

From the raw materials of our reputable suppliers to the shipment of the finished product, everything is subject to a complete quality control. On request, we can provide your ball bearings with a QR code.

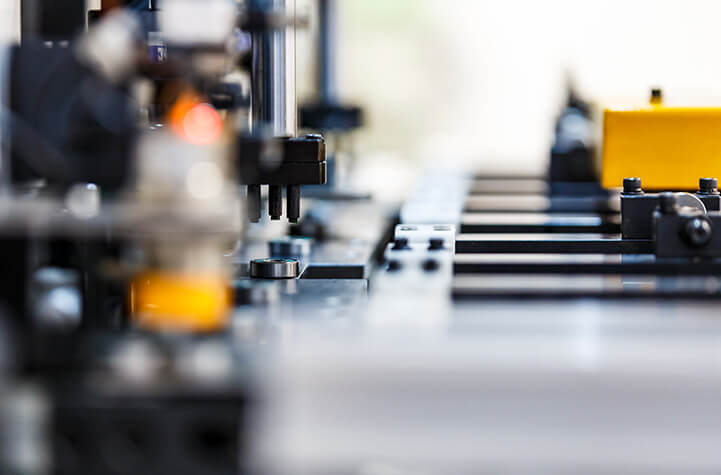

Here, too, we focus entirely on your specific requirements. Already in the production line all our products are 100% tested according to various criteria.

Upon delivery to our logistics center, random checks are carried out again, depending on the inspection plan. Your requirements are also the focus for packaging - with sustainable reusable containers if desired. In this way, we protect our environment as well as possible in addition to your products.

Our declared goal is to conserve our earth's resources and reduce negative environmental impacts as much as possible. To achieve this goal, we have implemented company-wide environmental standards (e.g. DIN EN ISO 14001) and developed appropriate measures. With our products and solutions, we contribute to increasing energy efficiency and reducing CO2 emissions.

For our plants, we have set ourselves the goal of reducing greenhouse gas emissions by 90% by 2040:

The consistent implementation of these packages of measures has already begun. For example, three of the six factories have installed photovoltaic systems to generate renewable energy.

Do you have specific questions about quality management, quality assurance or sustainability at CW Bearing? Then please feel free to contact me directly.